The right fastener for the right job

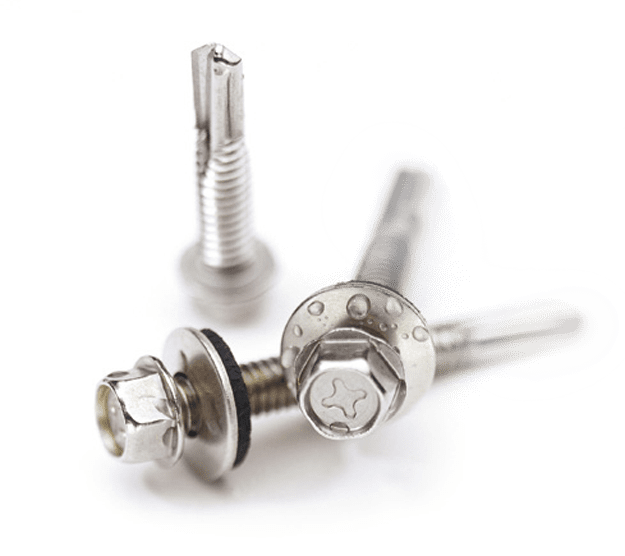

The fasteners are one of the most important components in most designs. Choosing the right screw, rivet or nail is important, and not always so easy. Various kinds of material must be joined. The choice of fastener material, dimensions, effective length and drilling capacity – everything must fit in order to produce the right results.

A wide range of products and an experience supplier make this task easier. U-nite has fasteners for most kinds of uses. You can find some good advice below, to help you choose the right products from our range. If you need more information, just contact U-nite.

Tips to help you choose the right product

1. Start with the material you are going to make your fixing it.

It’s important that you know what base material you are going to use your fastener in. This may be a wooden beam or a steel girder for instance. Unite supply fasteners that can be used in the following materials: • Wood • Light section steel / light steel framing • Hevy section steel / steel beam • Concrete

2. Choose product group

We have divided our products into groups, based on what is to be fixed, and into what material.

3. Choose corrosivity classification

The term “corrosivity classification” applies to the environment which the fastener is intended to. Our range spans classifications C1 to C5, which means every environment from clean indoor to outdoor environments with aggressive air pollutions. Remember that although stainless steel fasteners are more expensive, they are often the most economical choice in the long run. Choosing stainless steel fasteners is a cheap insurance policy.

4. The right corrosion protection class

It is important to know what requirements there are for the fastening’s corrosion resistance. Our range contains fastenings intended for corrosion protection classes C1-C5. These correspond to environments from clean indoor environments to outdoor environments with aggressive at- mospheric pollutants or salty air. Bear in mind that stainless steel fastenings certainly cost more to buy, but are frequently more economic over time. Choosing stainless steel is usually a cheap insurance policy.

5. The right drill capacity and dimensions

When you use a self-drilling screw, it is important that you know the thickness of the steel to which you want to fasten. A self-drilling screw is always intended for a specific range of sub- strate thicknesses. Bear in mind that the point can never drill deeper than its own length. The dimensions should be selected based on the loading and other conditions.

6. The right clamp length

Take care to ensure the screw’s clamp length (CL) is sufficient. The clamp length is always reck- oned from the outer surface to the inside of the substrate to which you are fastening. In other words, you must always count both the outer surface and the substrate in the clamp length.

7. The right colour

If the fastening is to be in a colour that matches the steel sheeting, it is important to choose the colour with care. Check the colour against the steel sheeting manufacturer’s designation and colour samples. The wrong colour can cause unnecessary waiting times and higher costs. Read more about Unite’s experience in painted construction screws on pages 96-97.

8. The right power screwdriver and speed

The recommended speed for self-drilling screws can be found under the installation instruc- tion on page 100. It is also on the packaging, so it is always available to the fitters. When you use self-drilling screws, it is important that you choose the right speed.

9. The right sockets and bit

Replace worn sockets, because they can damage the screw’s paint and surface treatment. Magnetic sockets should not be used with painted construction screws. They attract metal shavings that then stick and rust in the paint on the screws.

10. Avoid leaks

Never over-tighten screws with sealing washers so the rubber “flows out”. The mate- rial in our sealing washers is very high quality, but it can deform if tightened too hard.